Not known Details About Recycling Lives Services

Not known Details About Recycling Lives Services

Blog Article

Recycling Lives Services - Questions

Table of ContentsSome Of Recycling Lives ServicesThe Ultimate Guide To Recycling Lives ServicesThe Ultimate Guide To Recycling Lives ServicesThe Ultimate Guide To Recycling Lives ServicesSome Known Details About Recycling Lives Services All About Recycling Lives Services

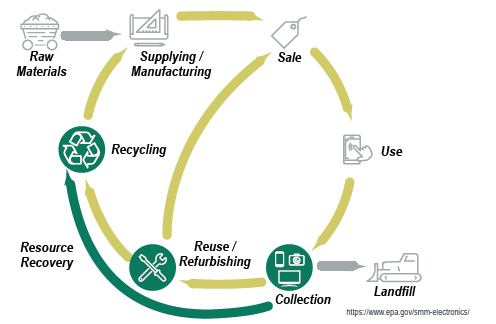

E-waste recycling is a lot more complex than conventional waste recycling. Generally, the very first step of the reusing procedure is manual sorting. As soon as e-waste is collected and transferred to the reusing facilities, employees sort the e-waste right into groups according to their kinds and models. All digital gadgets will be analyzed, and of which the parts that are still practical will certainly be drawn out to be reused; they can either be offered as individual parts or be combined to create a brand-new phone or computer system (recycling lives services).

Here, e-waste is thrown right into a substantial maker and is shredded right into little pieces, but prior to that, it has to first go through a process called de-manufacturing, which describes the activity of dismantling an item into components. https://www.mixcloud.com/rcyclng1vssvc/. This treatment is to remove all the possibly harmful products in electronic devices that will ruin the device or pollute the atmosphere as soon as got rid of right into land fills

What Does Recycling Lives Services Do?

Next off, the waste is more separated with water. At this phase, almost everything leftover are non-magnetic products; they will undergo an additional device filled with water, where materials with a low loved one thickness, mainly plastic, will certainly flow, while other materials, like glass, will sink. Lastly, prior to recycled materials are marketed, is to examine if there are any remaining important materials stayed with the plastic.

Some Known Factual Statements About Recycling Lives Services

Recycling e-waste not just avoids poisonous materials from entering our bodies and right into the atmosphere, yet the process also minimizes the dangerous ecological effects developed by the extraction and mining of virgin materials. Besides, the potential economic advantages that can be originated from this industry are substantial. The discarded e-waste in 2019 alone deserved greater than US$ 57 billion.

Computers and electronic tools are made from multiple kinds of plastic, steel, glass and rare-earth elements. Our goal when reusing electronic devices is to separate the various materials from each various other. The "product" we create from reusing is clean apart streams of recycled plastic, iron, steel, copper, light weight aluminum, glass and valuable steels.

2-1/2 min video clip reveals electronic devices being reused at a SLS facility. We get, sort and procedure computer equipment from services based on client particular requirements. The client records we are able to generate depends on how devices is handled prior to being reused. If the unit of measure for client records is by weight, pre-processing will include considering deliveries as they are received and manual removal of unsafe things (such as batteries).

The 30-Second Trick For Recycling Lives Services

Our significant recycling sites are geared up with automated industrial shredders, conveyor systems and sorting equipment. After risks are eliminated, the computer system tools is fed by conveyor into a huge shredder. The shredder rips the material into large items, about 2" to 6" in size. This initial step prepares the e-waste to start the procedure of separating plastic parts from steel, copper, aluminum, glass and various other assets.

After shredding, the conveyor belts push the e-waste with magnets, eddy currents, infrared cams and air jets. These modern technologies iron out various material kinds and separate arranged material from the e-waste stream. Iron and steel is separated from the e-waste, then aluminum, copper and circuit card are divided. After the bulk metal is gotten rid of, the e-waste stream, which is now primarily plastic, is more separated into abdominal wikipedia reference from polystyrene plastic.

The Basic Principles Of Recycling Lives Services

Separating Iron and Steel from e-Waste After shredding, conveyor belts transfer the shredded computer systems and e-waste under an effective magnet, which divides iron and steel from the shredded e-waste (recycling lives services waste electronics). The steel and iron are collected in pallet sized bags and prepared for sale as recycled commodity materials. Dividing Light Weight Aluminum, Copper and Circuit Boards from e-Waste After passing under the magnet, the e-waste remains to relocate by means of the conveyor belts with additional mechanical separators

A visual evaluation and hand sorting improves the high quality of the removed products. The apart streams of aluminum, copper, and motherboard are accumulated in pallet sized bags and prepared for sale as recycled asset materials. Benefits of Recycling Recycling vs - https://recyclinglivesservices.godaddysites.com/f/recycling-lives-services-transforming-waste-and-lives. Virgin Product The separated products are used to make future generation products

Using recycled material in the manufacturing of new products has benefits that go far beyond product reuse. It minimizes air pollution and carbon exhausts, decreases power and water usage and maintains helpful materials out of garbage dumps. As each asset is separated from the e-waste stream, the product is collected in pallet sacks or large cardboard boxes and delivered to an additional cpu or directly to a producer.

The Greatest Guide To Recycling Lives Services

It reduces contamination and carbon emissions, minimizes power and water intake and maintains helpful products out of land fills. SLS is at the forefront of establishing ingenious e-waste reusing remedies.

Customers can buy less points while reusing and reusing much more. Federal governments can develop e-waste management systems to collect and recycle, drawing out in a safe way several of the estimated $62.5 billion of value from discarded materials. Finally, companies can develop products created to last, not to be replaced, and to be reused.

Report this page